Jack hammers are power tools essential for heavy-duty construction, demolition, and roadwork projects. Designed to break through concrete, asphalt, and other tough materials, they deliver unmatched efficiency. However, their immense power also makes them potentially hazardous if not handled correctly.

This guide delves into the crucial safety measures and best practices for using a jack hammer.

How to Choose the Right Jackhammer for your job

Selecting the right jackhammer depends on the scope of your project, the materials you’re working with, and the available power source. Here’s a breakdown of the main types of jackhammers to help you make the best choice:

2.1 Pneumatic jackhammers

Powered by compressed air, pneumatic jackhammers are ideal for large-scale construction or demolition projects. They offer exceptional power, making them suitable for breaking dense materials like reinforced concrete or rock. However, they require a reliable air compressor and are best suited for outdoor environments.

2.2 Electric jackhammers

Electric jackhammers are versatile and user-friendly, making them an excellent choice for indoor or residential applications. They are quieter and lighter than pneumatic demolition breakers, delivering sufficient power for medium-duty tasks such as breaking up concrete slabs or tile removal. They are also more portable, requiring only an electrical outlet to operate.

2.3 Gas-powered jackhammers

Highly portable and independent of electrical or air sources, gas-powered jackhammers are designed for remote or outdoor projects. They provide robust power for heavy-duty applications but tend to be heavier and noisier, making them less suitable for enclosed spaces.

How to Choose the Right Bit for Your Project

The choice of jackhammer bit plays a crucial role in the efficiency and quality of your work. Each type of chisel is designed for specific tasks and materials. Here’s a guide to help you select the right bit for your project:

3.1 Point Chisel

The point chisel is designed for precision and power. Its sharp, pointed tip concentrates the rotary hammer‘s force on a small area, making it ideal for breaking through dense materials like concrete or rock. This bit is commonly used for creating holes or starting cracks in hard surfaces.

3.2 Flat Chisel

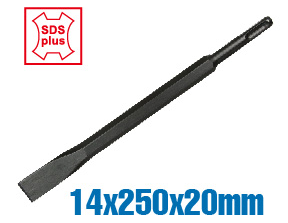

FHCS114020

SDS plus flat chisel 20mm

The flat chisel has a wide, flat tip, making it versatile for cutting, prying, and general-purpose demolition. It’s especially effective for breaking up concrete slabs or removing tiles. The flat design provides more surface coverage, speeding up tasks while maintaining precision.

3.3 Wide Chisel

For larger-scale tasks, the wide chisel is the go-to option. Its broader tip is perfect for removing large sections of material, such as stripping asphalt or breaking up expansive concrete surfaces. It’s an excellent choice when efficiency and coverage are priorities.

By selecting the appropriate bit for your project, you can enhance the performance of your demolition hammer and achieve professional results with less effort.

Precautions for Using an Electric Concrete Breaker

Operating an electric concrete breaker is a high-intensity task. Correct usage and adherence to safety measures not only improve work efficiency but also minimize the risk of accidents. Below are key precautions to follow when using demolition jack hammer:

4.1 Preparing for Safe Operation

4.1.1 Equipment Check:

- Inspect the hammer drill for any visible damage or wear, such as cracks, loose parts, or faulty connections.

- Ensure all components, including bits, power cords, or hoses, are securely attached and functioning properly.

- Test the heavy duty jackhammer on a low-power setting to confirm smooth operation before starting your task.

4.1.2 Personal Protective Equipment (PPE):

- Wear safety goggles to protect your eyes from flying debris.

- Use ear protection such as earplugs or earmuffs to safeguard against prolonged noise exposure.

- Put on heavy-duty gloves to maintain a firm grip and reduce hand fatigue.

- Wear a dust mask or respirator if working in dusty environments.

- Ensure sturdy, steel-toed boots are worn to protect your feet from falling debris.

4.2 Setting Up the Workspace

- Clear the area of unnecessary tools, materials, and hazards that could impede your movement.

- Use barricades or warning signs to keep bystanders at a safe distance.

- Assess the ground stability and ensure solid footing before starting work.

- Check for hidden utilities, such as pipes or electrical lines, before breaking into surfaces.

4.3 Operating the Concrete Hammer

4.3.1 Correct Posture and Grip:

- Stand with feet shoulder-width apart for stability.

- Hold the demolition hammer breaker firmly with both hands, ensuring your arms and shoulders absorb the vibrations.

4.3.2 Safe Start-Up:

- Position the jackhammer’s bit correctly on the surface before starting the tool.

- Turn on the demolition drill gradually, ensuring you are in full control of its movements.

4.3.3 Controlled Use:

- Apply steady pressure without forcing the drill hammer into the surface; let the tool’s weight and power do the work.

- Avoid prolonged continuous operation to prevent overheating and operator fatigue.

- Always be aware of your surroundings and stop immediately if unsafe conditions arise.

4.4 Post-Operation Steps After Using an Electric Jackhammer

After using an electric jackhammer, follow these essential steps:

- Turn Off and Disconnect Power: Switch off the jackhammer (e.g., Makita jack hammer, Bosch jack hammer) and unplug it to prevent accidental start-up.

- Clean the Equipment: Remove dust and debris from the bit, vents, and handles using a damp cloth.

- Inspect for Damage: Check the tool, power cords, and bits for any signs of damage or wear before each use.

- Lubricate Regularly: Clean and lubricate the tool as recommended by the manufacturer to ensure smooth operation.

- Replace Worn Parts: Promptly replace any worn or damaged components to maintain performance and safety.

- Store Properly: Keep the jackhammer in a dry, secure location when not in use.

- Dispose of Waste: Safely clean up any debris from the worksite.

Following these steps will ensure the electric jackhammer and other small construction equipment remain in excellent condition, operate safely, and maintain a clean and secure work environment.

FAQ

5.1 How long can you use a jackhammer?

A jackhammer’s usage time depends on its type, workload, and safety practices:

- Industrial Models: Can run 2-4 hours with breaks to prevent overheating.

- Light-Duty Models (Hand Held Jack Hammer): Best used in 30-minute to 1-hour intervals.

- Safety: Take breaks every 15-30 minutes to avoid fatigue and vibration injuries.

- Cooling: Let the tool cool for 10-15 minutes after continuous use.

Always follow the manufacturer’s guidelines for optimal performance and safety.

5.2 What should I do if the jackhammer drill jams?

- Stop the tool immediately.

- Turn off and disconnect the power source.

- Gently remove the tool from the jammed area without forcing it.

Conclusion

Using a demolition hammer effectively and safely requires proper preparation. By setting up the workspace carefully, maintaining correct posture, and following operational guidelines, you can complete your tasks efficiently while minimizing risks. Regular maintenance of the jackhammer and a commitment to safety are key to ensuring a successful project.

If you’re looking for a reliable demolition hammer supplier, we recommend the FIXTEC Demolition Hammer. FIXTEC is a trusted demolition hammer band that can provide top-tier performance.

Why Choose FIXTEC?

- Over 20 Years of Experience: Proven expertise in OEM and marketing.

- Extensive Product Selection: Access to 2500+ tools tailored to various needs.

- Efficient Operations: A 10,000m² warehouse with a low MOQ.

- Global Network: Supplying tools to 250+ countries, including South America, Southeast Asia, Europe, North America, the Middle East, and Africa.

- Certified Quality Assurance: CE, EMC, GS, RoHS, and ETL certifications guarantee compliance with international safety standards.

If you choose FIXTEC, we will serve you with dedication. We warmly welcome you to visit the FIXTEC website to learn more.